About us

Our goal in this factory is to produce aluminum sheets for various industries, including kitchen equipment, sheets, aluminum melting and rolling, while considering environmental, economic, and social requirements to address the needs related to the aluminum industry

Our History

Get to know more about Noord Pars

Navard Pars Factory was established in 1358 (1979) on Aab Ali Road, 35-Meter Union Street, on a land with an area of … by the private sector. Aluminum sheet production in this factory takes place using experienced human resources, unique production and laboratory equipment, and modern metallurgical facilities. We are capable of producing aluminum slabs in this factory.

In this factory, various types of plates, sheets, and rounds, meaning large-sized sheets with different alloys, are manufactured. It is worth mentioning that Noord Pars Factory is among the first and only factories capable of producing discs with dimensions of eight thousand.

[Note: The text you provided seems to be incomplete as you’ve left out the area of the land and the number of discs produced. Please fill in the missing information if needed.

Standards of Products at Tochal Navard Pars

We have a metal testing laboratory

We have a metal testing laboratory

We have a metal testing laboratory

We have a metal testing laboratory

Factory Departments

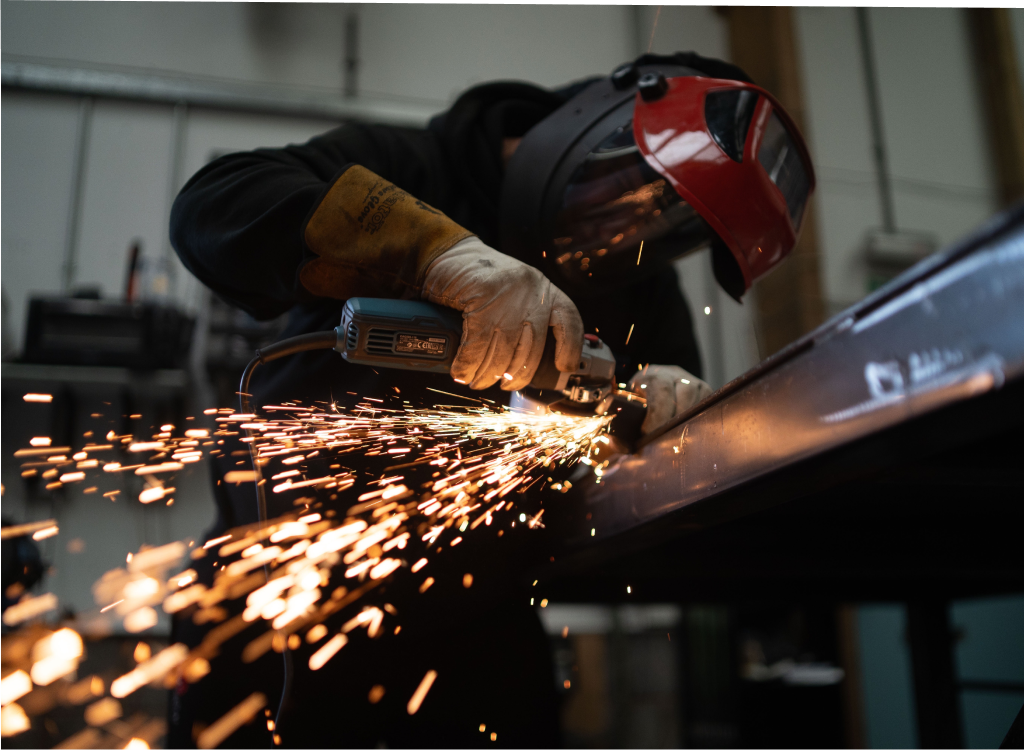

Advanced and well-equipped units for superior production of aluminum sheets and plates using cutting-edge technologies

These units are dedicated to providing high-quality products and international standards, utilizing state-of-the-art equipment and modern laboratories. Through the expertise of our experienced workforce, we aim to achieve high-precision manufacturing, high flexibility, and customer satisfaction

Casting Unit

In this unit, which is one of the most essential components for aluminum product manufacturing, metals in the form of ingots and aluminum scraps are first introduced. Initially, these metals are transformed into a liquid state, then poured into molds to solidify. Essentially, this process shapes the metals and significantly influences their mechanical and chemical properties."

Casting Unit

In this unit, which is one of the most essential components for aluminum product manufacturing, metals in the form of ingots and aluminum scraps are first introduced. Initially, these metals are transformed into a liquid state, then poured into molds to solidify. Essentially, this process shapes the metals and significantly influences their mechanical and chemical properties."

Molding Unit

In this unit, which is one of the most essential components for aluminum product manufacturing, metals in the form of ingots and aluminum scraps are first introduced. Initially, these metals are transformed into a liquid state, then poured into molds to solidify. Essentially, this process shapes the metals and significantly influences their mechanical and chemical properties."

Casting Unit

In this unit, which is one of the most essential components for aluminum product manufacturing, metals in the form of ingots and aluminum scraps are first introduced. Initially, these metals are transformed into a liquid state, then poured into molds to solidify. Essentially, this process shapes the metals and significantly influences their mechanical and chemical properties."